5 Ton Portable Gantry Crane 8-Wheel Design Buyer’s Guide

A Buyer’s Guide to Mobile, Rolling, and Non-Rail Gantry Cranes, Reducing Floor Load While Improving Stability, Safety, and Long-Term Usability

Introduction: Why Buyers Are Choosing Portable and Mobile Gantry Cranes

A 5 ton portable gantry crane is often the first choice for workshops that need lifting power without installing a permanent crane system. Many factories do not want to add runway beams, columns, or roof supports. Others simply cannot, due to building limits or rental agreements. A portable gantry crane avoids these problems and keeps the workshop layout flexible.

Common Names for Portable Gantry Cranes

This type of crane may be called different names, such as:

- Mobile gantry crane

- Rolling gantry crane

- Non-rail gantry crane

The names vary, but the function is the same. The crane moves directly on the floor, does not need rails, and can be used in different areas of the workshop as needed.

Why Buyers Choose Portable Gantry Cranes

From a buyer's point of view, the reasons are practical and straightforward:

- Flexible lifting locations: Loads can be lifted in more than one position, without being limited to a fixed runway.

- No building changes required: No structural steel, no civil work, and no downtime for installation.

- Works with existing concrete floors: The crane is designed to operate on the current floor, without reinforcement.

Typical Application Areas

These advantages make mobile and rolling gantry cranes common in maintenance workshops, assembly areas, and tool or mold handling zones.

The Real Limit Is Often the Floor, Not the Crane

Most buyers start by asking whether a crane can lift 5 tons. That is understandable. But in many projects, the real limit is the floor bearing capacity, not the lifting capacity.

Important Floor Load Factors Buyers Often Miss

- The load is carried by the crane wheels, not spread evenly across the floor

- Each wheel applies high pressure to a small area

- Starting, stopping, and lifting add extra stress to the floor

Buyer Reality

Buyer reality:: A gantry crane may be rated for 5 tons, but your concrete floor may not be able to safely support it.

Why Floor Limits Drive Gantry Crane Design Changes

This is why floor limits often lead buyers to consider design changes, such as increasing the number of wheels, to reduce wheel load and protect the floor.

Project Conditions Buyers Must Define Before Selecting a Gantry Crane

Before requesting a quotation or comparing different gantry crane designs, buyers need to clearly define the basic project conditions. These parameters are used only as a reference for preliminary selection and pricing, but they directly affect crane structure, wheel design, and safety margins. Incomplete or unclear information at this stage often leads to inaccurate quotes or unsuitable crane configurations later.

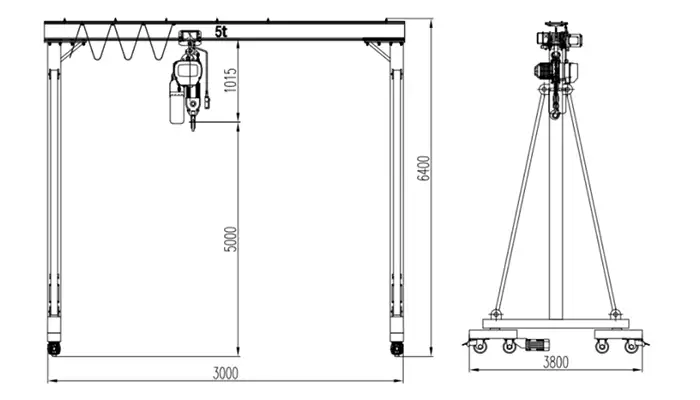

Clear definition of operating conditions helps suppliers calculate loads correctly and recommend an appropriate design:

- Rated capacity: 5 ton gantry crane

- Span: 3 meters

- Lifting height: 5 meters

- Power supply: 415V, 3-phase

- Operating mode: Floor-mounted, non-rail gantry crane

Critical constraint:Maximum allowable floor load: ≤ 1.5 ton per square meter

Buyer note:: This floor load limit is a key decision factor. It directly determines whether a standard 4-wheel design is acceptable or if an 8-wheel rolling gantry crane is required to keep wheel pressure within safe limits.

Why Standard 4-Wheel Mobile Gantry Cranes Are Often Not Suitable

From a buyer’s perspective, a standard 4-wheel mobile gantry crane may look sufficient on paper, especially when the rated capacity matches the lifting requirement. In practice, however, this design can introduce risks that are not obvious during the quotation stage. These risks are mainly related to how the load is transferred to the floor.

With only four wheels supporting the entire crane and load:

- The total weight is concentrated on fewer contact points

- Each wheel carries a higher share of the load

- Wheel pressure increases significantly, especially under full load

This higher wheel pressure can damage concrete floors over time, even if no immediate cracking is visible.

The risk becomes greater during normal operating actions, such as:

- Dynamic lifting, when the load first leaves the ground

- Sudden braking while moving the crane

- Load positioning, especially with off-center or uneven loads

These moments create short-term peak loads that exceed static calculations and place extra stress on the floor.

Hidden cost for buyers:: Problems often appear after installation. Floor cracking, forced reinforcement work, usage restrictions, or limits on where the crane can travel may all occur. In many cases, these costs exceed the price difference between a 4-wheel and a properly designed multi-wheel gantry crane.

8-Wheel Design: The Optimal Solution for a 5 Ton Portable Gantry Crane

When floor bearing capacity is limited, increasing the lifting capacity alone does not solve the problem. What matters is how the total weight of the 5 ton portable gantry crane and the lifted load is transferred to the floor. This is where an 8-wheel mobile gantry crane design becomes the most practical option for buyers.

How an 8-Wheel Mobile Gantry Crane Reduces Wheel Pressure

The main advantage of an 8-wheel design is simple and effective. Instead of concentrating the load on four wheels, the total weight of the crane and the lifted load is shared across eight contact points. This change has a direct impact on floor stress.

In real operating conditions, this means:

- The total crane load is distributed across 8 wheels instead of 4

- Individual wheel load is significantly lower

- The design can meet low floor bearing capacity limits that a 4-wheel crane cannot

Operating on Floors with Limited Bearing Capacity

As a result, an 8-wheel rolling gantry crane can operate safely on:

- Standard industrial concrete floors

- Older factory floors with limited design margins

- Non-reinforced slabs where civil modification is not an option

For buyers, this often removes the need for floor strengthening or restricted operating zones.

Designed Specifically for Non-Rail Applications

An 8-wheel configuration is especially suited to non-rail gantry crane applications. The crane is designed to travel directly on the floor, without any permanent guiding system.

Key features include:

- Fully floor-traveling gantry crane design

- No embedded rails or steel tracks

- A true portable gantry crane solution that can be relocated as needed

This makes the 8-wheel mobile gantry crane ideal for workshops that require flexibility while still operating within strict floor load limits.

Advantages of an 8-Wheel Rolling Gantry Crane (Beyond Floor Load)

Choosing an 8-wheel rolling gantry crane brings more benefits than just reducing wheel pressure. For buyers, these advantages translate into safer operation, smoother handling, longer equipment life, and greater flexibility in workshop layout.

Improved Stability and Safety

With more wheels sharing the load, the crane is naturally more stable. This reduces risks associated with lifting and moving heavy loads.

- Better resistance to side loading

- Reduced sway when lifting off-center or uneven loads

- Increased operator confidence during daily use

A stable crane means fewer accidents and safer handling for both people and equipment.

Smoother Traveling and Load Control

Distributing the crane weight across 8 wheels makes it easier to move and control. This results in smoother operation, even on delicate floor surfaces.

- Lower rolling resistance per wheel

- Reduced vibration during movement

- Suitable for sensitive floor types such as: Epoxy-coated floors, Polished concrete, Finished workshop surfaces

This ensures loads can be positioned accurately without shaking or jolting, improving overall efficiency.

Longer Floor and Crane Service Life

An 8-wheel design spreads stress evenly across the floor and the crane wheels. This helps protect both the workshop and the crane itself over the long term.

- Reduced point stress on concrete floors

- Less wheel wear thanks to balanced load sharing

- Lower long-term maintenance costs for both crane and floor

For buyers, this reduces repair costs and downtime, making the investment more cost-effective.

Greater Operational Flexibility for Buyers

Finally, the 8-wheel crane design allows for more flexible workshop operations. It can be easily moved and adapted to changing production needs.

- Easy relocation between workstations

- Suitable for temporary production lines

- Ideal for expanding or rented facilities

This flexibility is particularly valuable for buyers who need a mobile or non-rail gantry crane that can adapt to changing workflow requirements.

Key Design Specifications Buyers Should Confirm When Requesting a Quote

Before placing an order, buyers should make sure that the gantry crane design matches both operational needs and floor limitations. Confirming the right specifications helps avoid surprises during installation or operation and ensures safe, efficient lifting.

Some key points to check include:

- Wheel quantity and layout – Make sure the crane uses the planned 8-wheel configuration to reduce wheel pressure.

- Individual wheel load – Confirm the maximum load each wheel will carry at full rated capacity.

- Wheel material – Choose the right type for your floor and load: PU, nylon, or steel wheels.

- Load equalization or bogie design – Ensures all wheels share the load evenly, especially on uneven floors.

- Safety factor for dynamic operation – Accounts for acceleration, braking, and off-center lifting.

- Hoist type – Ensure the hoist is compatible with a 5 ton portable gantry crane and your specific lifting requirements.

Procurement tip: Don’t just ask for the crane’s rated capacity. Always request the maximum wheel load per wheel, as this determines whether your floor can safely support the crane in operation.

Cost vs. Value: Why Buyers Choose an 8-Wheel Portable Gantry Crane

At first glance, an 8-wheel portable gantry crane may cost a little more than a standard 4-wheel design. However, when looking at the bigger picture, it often proves to be the more practical and economical choice for buyers.

Because of the way the weight is distributed, an 8-wheel design can eliminate extra costs that usually come with floor and building modifications:

- No need for floor strengthening – The crane works safely on existing concrete.

- No rail installation costs – Unlike fixed overhead or rail-based gantry cranes, there’s no track or runway to install.

- No production downtime for civil work – Operations can continue while the crane is installed.

- Lower risk of structural damage – Floors, beams, and other building elements are less likely to be affected.

Result: Over the full service life of the crane, buyers often save more money than the small extra upfront cost. The total ownership cost is lower, and the crane can be used safely and flexibly for years to come.

Typical Applications of 5 Ton Mobile and Rolling Gantry Cranes

A 5 ton mobile or rolling gantry crane is designed to provide lifting flexibility where traditional fixed cranes are not practical. Its ability to move freely and work on existing floors makes it suitable for a wide range of industrial applications.

Common applications include:

- Mechanical assembly workshops – For lifting and positioning heavy machinery components without permanent runway cranes.

- Mold and tooling handling – Easy movement of molds, dies, and other tooling between workstations.

- Equipment maintenance areas – Supports repair and servicing tasks where lifts are needed temporarily or in multiple locations.

- Warehouses with flexible layouts – Ideal for areas where inventory or storage racks change frequently.

- Plants using non-rail gantry cranes – Perfect for facilities with floor or structural limitations that prevent rail installation.

These applications show how mobile, rolling, and non-rail gantry cranes can provide practical, cost-effective lifting solutions for a variety of industrial environments.

Conclusion: A practical buying strategy for 5‑ton gantry cranes

A 5‑ton portable gantry crane should be chosen based on what the floor can safely handle, not only on the crane’s lifting rating. Even if the crane can lift 5 tons, too much pressure under the wheels can damage the floor, create safety issues, or force costly repairs later.

What the 8‑wheel design gives you

- Lower wheel pressure: Spreads the load across more wheels, so each wheel presses less on the floor. That helps keep the floor safe when bearing capacity is tight.

- Better safety: More stable handling, less sway, and easier control when lifting or moving loads. That makes daily use simpler for operators, and reduces the chance of problems.

- Stronger long‑term value: Less wear on the floor and on wheels, fewer repairs, and less need for expensive civil work or reinforcement. Over years of use, this often costs less than a cheaper but riskier design.

Who benefits most

Buyers who need a rolling or non‑rail gantry crane in places where the floor has strict load limits will usually find the 8‑wheel configuration to be the most balanced choice. It keeps lifting operations within safe floor limits, while staying flexible enough to move around the workshop or plant as needs change.

A helpful note for buyers

It’s useful to think of floor limits and wheel pressures the way industry guides describe differences between floor load capacity and ground or wheel bearing pressure, since they’re related but not the same thing.This is part of why reducing pressure per wheel matters in practice, not just in theory.

Also, practical safety standards remind users to clearly mark rated loads and use cranes within safety guidance, which supports careful selection and use of the right crane for the job.

In short: when floor strength is a real limit, go with a design that protects the floor, keeps operations safe, and holds value over time. An 8‑wheel portable gantry crane does exactly that.